Industry Initiatives

Ophthalmic manufacturers can significantly reduce environmental impact by adopting more sustainable practices, such as minimizing packaging, enhancing instrument re-usability, and optimizing manufacturing and distribution processes. These innovative strategies are showcased below, offering ophthalmologists solutions for delivering environmentally responsible eye care.

What's Important - Industry Initiatives

How the Industry Can Make an Environmental Impact

Large manufacturers who produce the drugs and devices that we use in surgery are uniquely positioned to make an environmental impact by reducing packaging, making instruments reusable, and streamlining their manufacturing and distribution process. Many companies share the priority of preserving our world for the future. Several have already implemented significant environmentally friendly changes and continue to prioritize internal efforts to lower their carbon footprint.

Because we believe that companies are not competitors but collaborators when it comes to the environment, we invite them to share their challenges, opportunities, and lessons learned.

Key Industry Initiatives

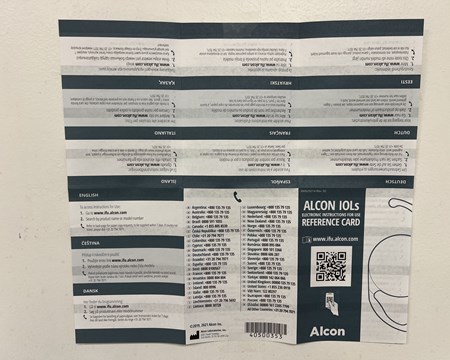

Sustainable Packaging

Learn how eIFUs and innovative materials like green foam are transforming how we think of packaging for ophthalmic products.

View Sustainable Packaging

Reusable Blades

Consider multi-use rather than single-use, disposable blades to reduce waste and save costs in the OR.

View Reusable Blades

Reusable Phaco Cassettes

Discover options for reusable phaco and I/A hand-pieces/tips that significantly reduces the environmental footprint for each case.

View Reusable Phaco Cassettes

Surgical Drapes

Explore alternatives to full-body surgical drapes which contribute to unnecessary OR waste.

View Surgical DrapesA Summarized Approach to Sustainability Measures for Health Systems and Industry

This document represents a summary of two roundtables held between health systems, group purchasing organizations (GPOs), and MedTech companies to identify areas of collaborative action that can be taken to reduce healthcare value chain emissions. Key approaches to decarbonization are mapped on a 24-month roadmap as actionable steps that can be taken by individual companies for greater collective progress. As climate-related health crises continue to act as a force multiplier disproportionately affecting populations already experiencing health inequity, collective action steps described in this article can serve as a compounding solution both for the health of individuals and for the business of healthcare. Options for collective action are provided in categories of product innovation, product utilization and clinical engagement, and transportation and logistics with emphases on packaging, composition, takeback programs, durability, reprocessing and reformulation, and efficiency. These best practice recommendations for management and cooperation can serve as valuable guidance as health systems and suppliers continue to face changes to disease prevalence and supply demand among other climate-related vulnerabilities.

Corza Medical efforts to prioritize maintenance and education of instruments for ophthalmic surgery

Corza Medical, a leading global medical technology company that specializes in innovative surgical solutions and technologies, is announcing efforts to prioritize maintenance and education of instruments for ophthalmic surgery. Their goal is to create longer product lifecycles and greater awareness around the proper handling and preservation of ophthalmic instruments.

Corza is seeking to reduce the frequency with which new surgical instruments are replaced by educating (onsite or virtual) operating room (OR) and sterile processing staff on proper care techniques. Services offered by Corza include:

- ACT (Assess, Correct, Tune): systematic inventories of surgical trays to evaluate instrument status and tray integrity.

- BEST (Bringing Efficiency to Surgical Trays): surgical tray optimization of safety, efficiency, productivity, inventory control, and cost-savings.

- Practical support for operating room, decontamination, assembly/sterilization, instrument care, and clinic teams.

- Site visits for identification of opportunities for improvement and best-practices implementation.

These efforts support their belief that well-cared-for reusable surgical instruments can perform effectively for longer.

BVI Champions Sustainable Progress with Global ESG Initiatives

In an era where sustainability is no longer optional but essential, BVI is demonstrating meaningful leadership by embedding environmental, social, and governance (ESG) practices into its global operations. The organization has made notable strides in reducing its environmental footprint and encouraging industry-wide progress.

Industry Partners

Industry Advisory Board

John Hovanesian

Principal at Harvard Eye Associates, Chair Industry Initiatives Advisory Board

Andrew Ihan Chang

Chief Commercial Officer at BVI Medical

Chuck Hess

Global VP Development & Operations, Bausch + Lomb

Erik Bonn

Chief Commercial Officer

Microsurgical Technologies

Erin Powers

Vice President, Johnson & Johnson Vision

Jessica Raab

Director of Medical Education, Corza Medical

Mikhail Boukhny

Mikhail Boukhny

VP Global R&D, BVI

Thomas Bosshard

Co-CEO and Board Member of Oertli Instrumente AG

Industry Editorial Board

John Hovanesian, MD

Chair Industry Editorial Board

Ashraf Ahmad, MD

Stephanie P Chen, MD

David Crandall, MD

Andrew Keyser, BS

Brenda Nuyen, MD

Audrey Talley Rostov, MD

Emily Schehlein, MD

Paul Ursell, MD

This information and any links to company websites are provided solely for informational purposes as they relate to sustainability. EyeSustain, the American Academy of Ophthalmology, ASCRS, and ESCRS disclaim any endorsement of any individual manufacturer or product. EyeSustain has not received financial support from any ophthalmic manufacturer.